METO is a trusted brewery, kombucha and distillery equipment manufacturer with global turnkey solutions and custom fabrication services.

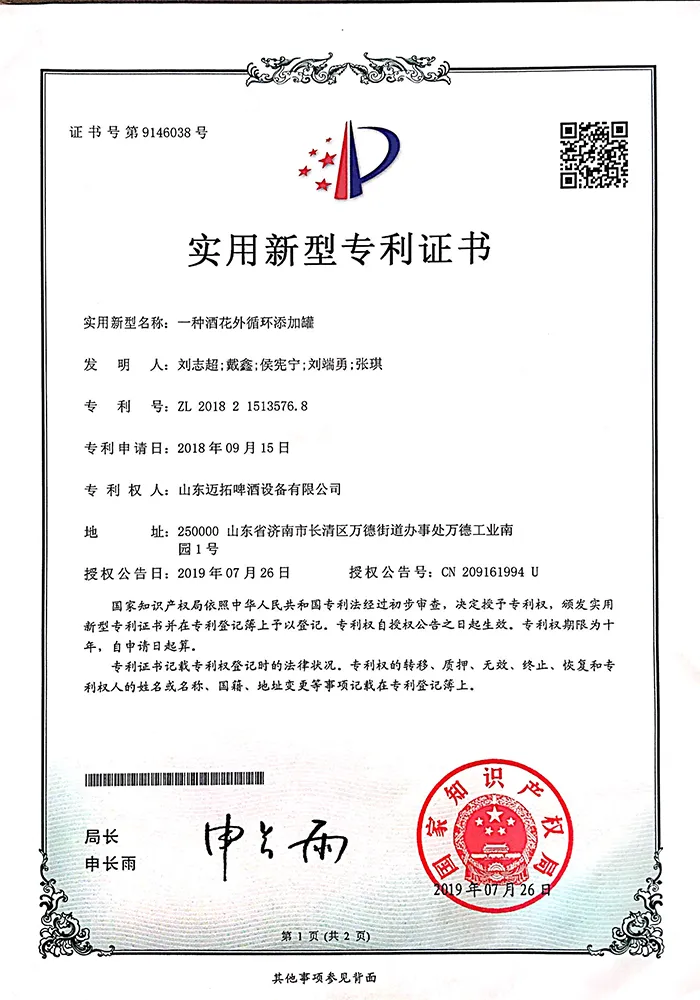

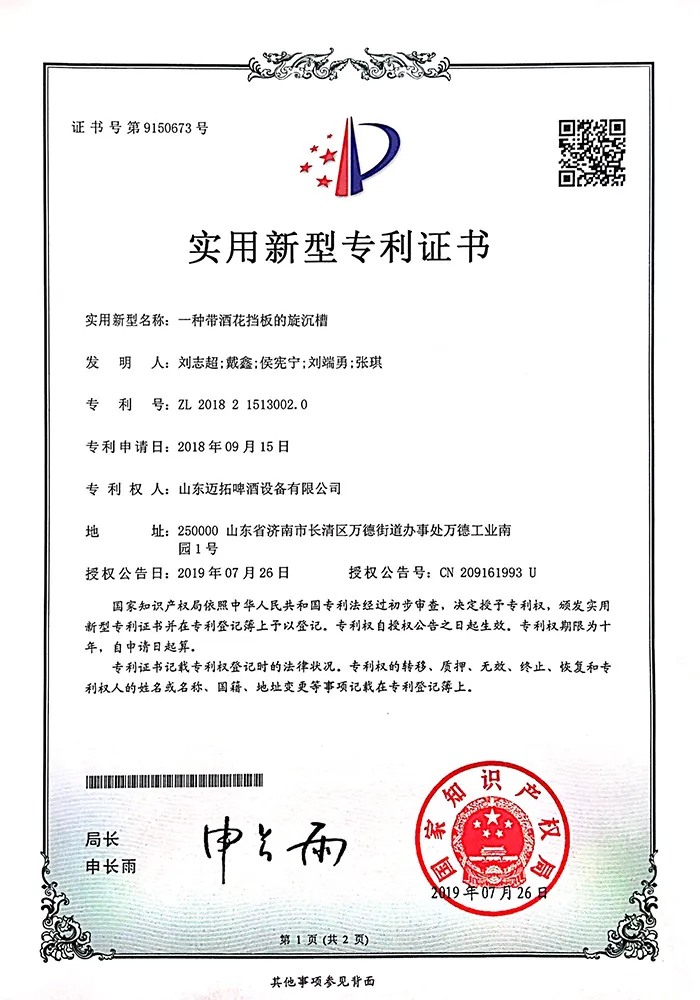

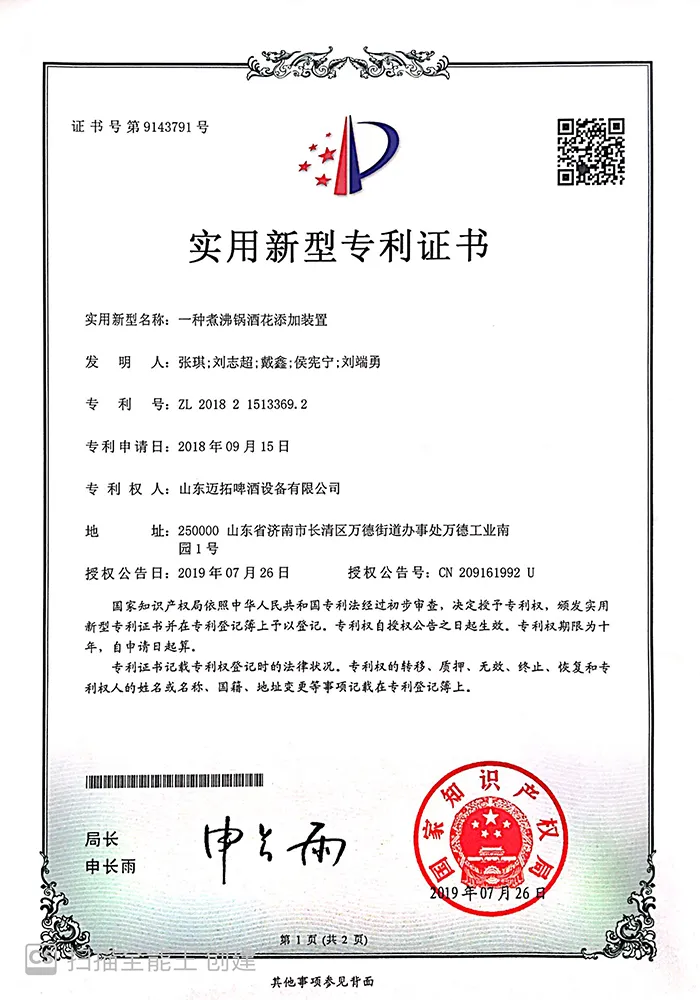

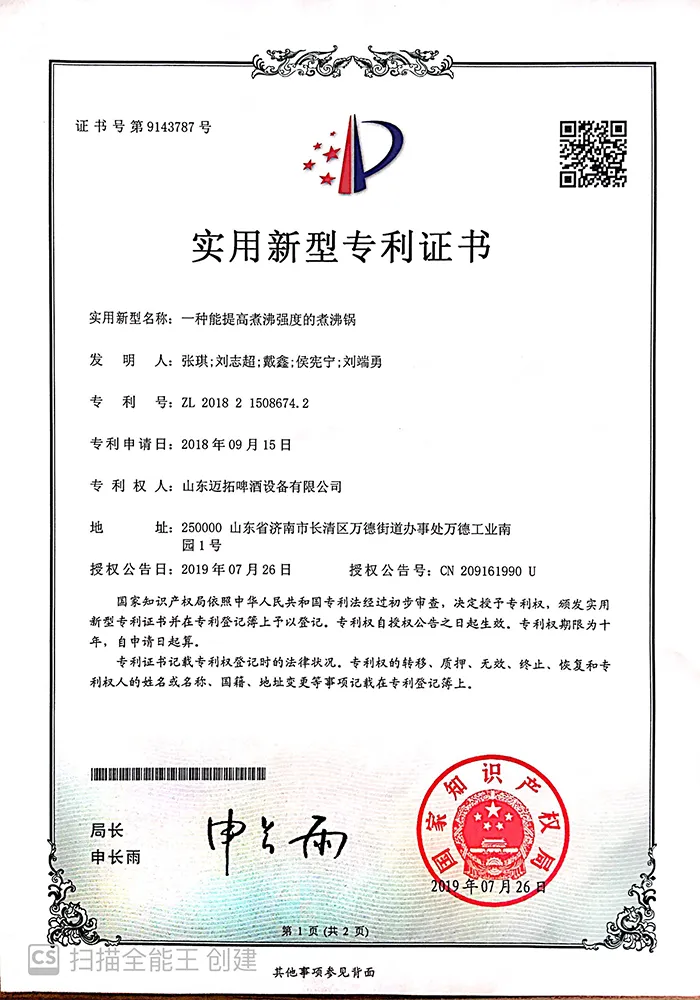

Founded in 2013, Maituo Equipment is a national high-tech enterprise specializing in the research, development, and manufacturing of brewing equipment, bio-fermentation equipment, distillation equipment, and stainless steel containers. Its subsidiary, Shandong Maituo Intelligent Equipment Co., Ltd., is headquartered in the Jinan Economic Development Zone, covering over 30,000 square meters. The company boasts multiple automated production lines and advanced processing centers, along with comprehensive manufacturing and quality inspection systems.

Our services cover beer, kombucha, distillation, and wine systems, as well as various fermentation tanks, CIP (Cleaning in Place) tanks, and stainless steel tanks. We strictly implement 48-hour pressure testing and full-process quality inspection, supporting OEM/ODM customization and global delivery.

We’re a cross-disciplinary team of process engineers, brewers, and project managers specializing in brewery, kombucha, distillery, winery, and stainless-steel tank systems. From 3D design and ASME-grade welding to FAT/SAT, installation, and lifetime after-sales, we deliver fast, precise, and safe outcomes for every project.

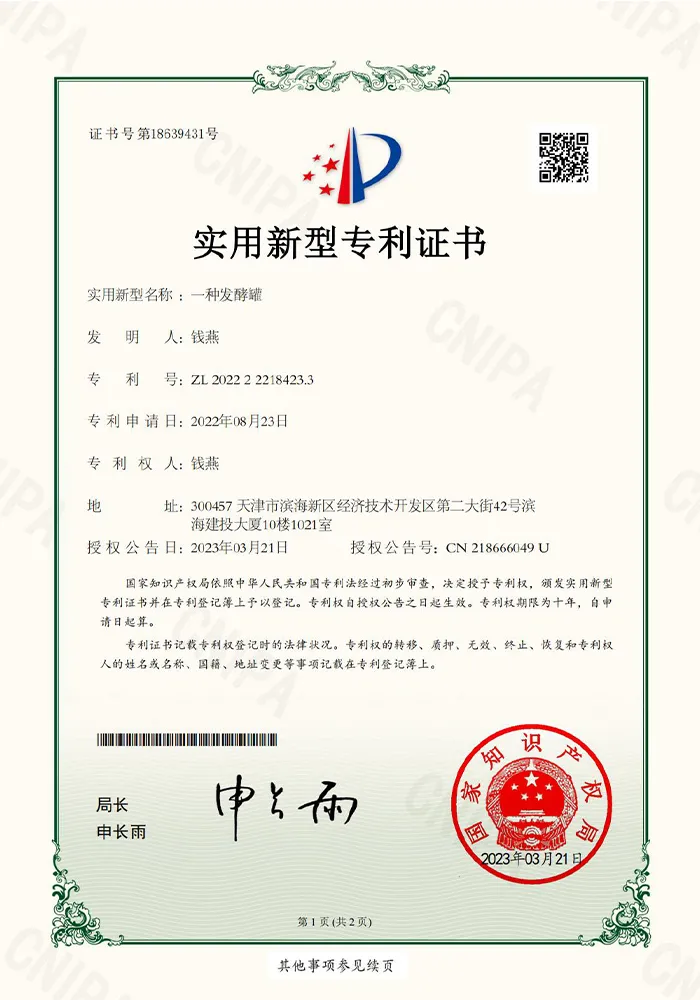

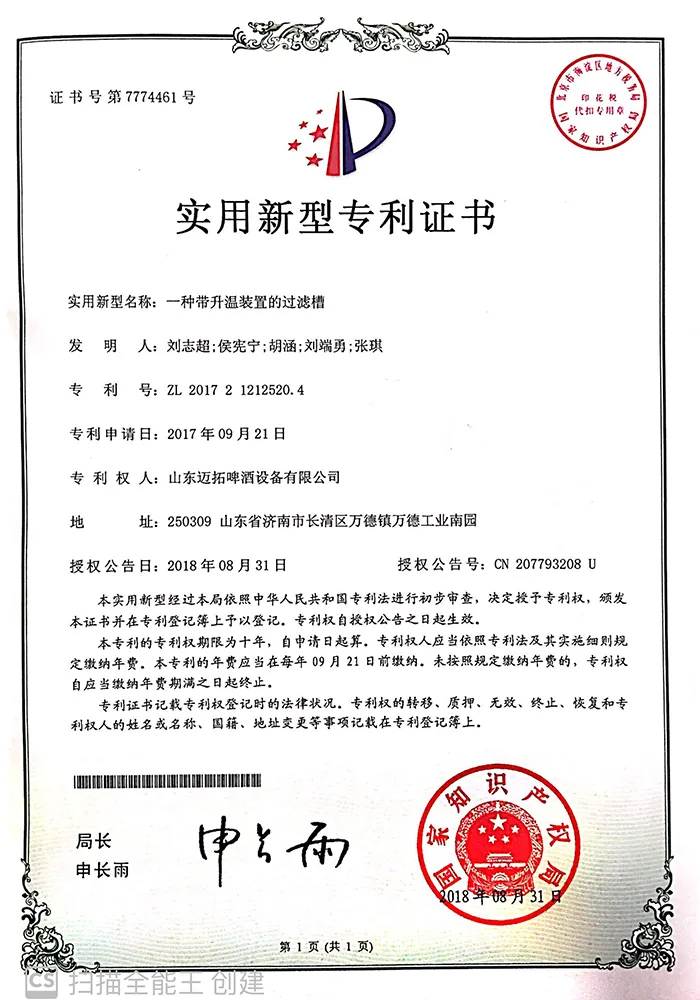

METO provides craft breweries, wineries, rice wine workshops, and distilleries with one-stop fermentation solutions, from design and customization to installation, commissioning, and after-sales service. Its core products include brewing systems for beer, wine, rice wine, and distilled spirits, supporting customization in a variety of capacities and configurations.

From demand to production, we use standardized processes and milestone management to ensure that each link is traceable, acceptable, and delivered on time. The project manager is responsible for the entire process, and multiple teams such as engineering, process, quality, logistics, and after-sales work together in parallel to reduce communication costs and implementation risks.

High-precision deburring and edge shaping for perfectly flat weld/assembly surfaces

Sanitary TIG welding by expert welders for robust seams and hygienic inner surfaces.

Lean assembly with full FAT, electrical & piping pre-installed for true plug-and-play delivery.

Mirror finishing to Ra≤0.4μm (≤0.2μm optional), eliminating hygiene dead corners for easy CIP/SIP.

From raw materials to finished products, every step is visualized

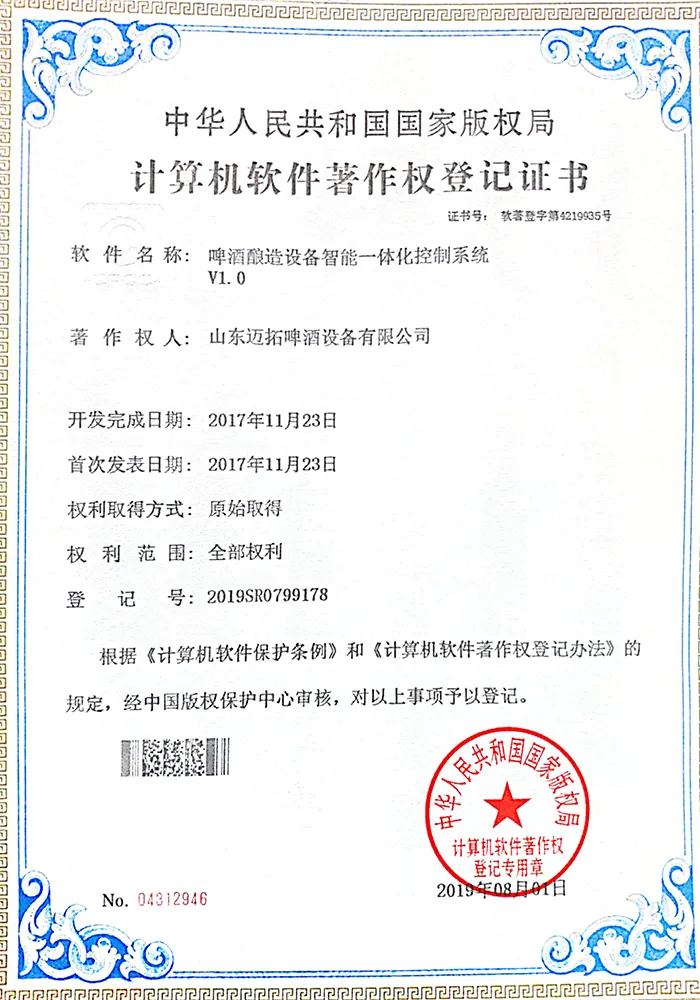

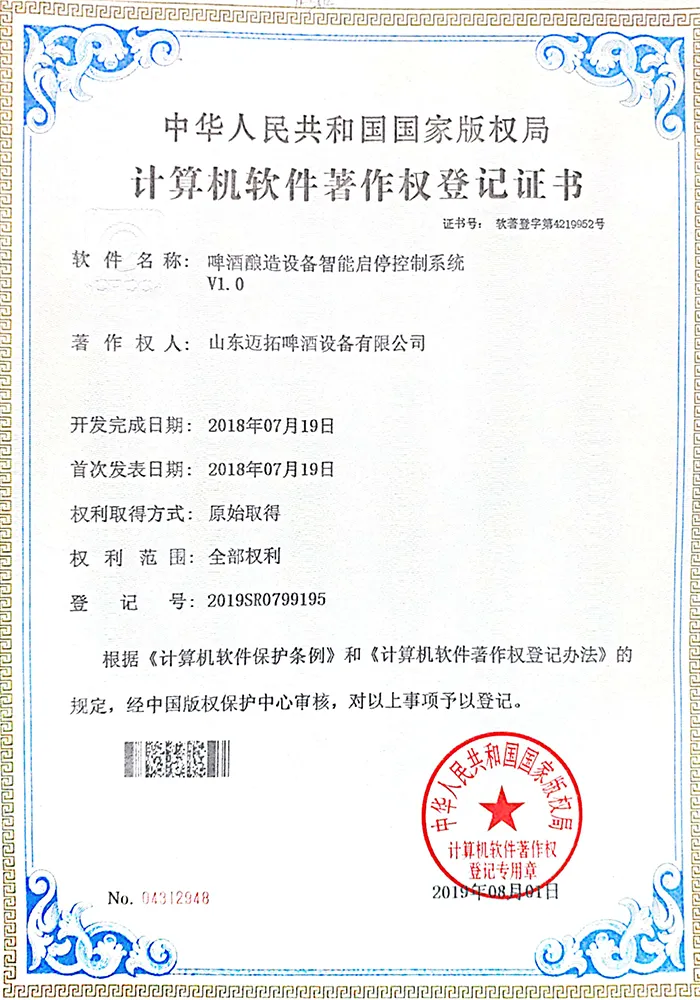

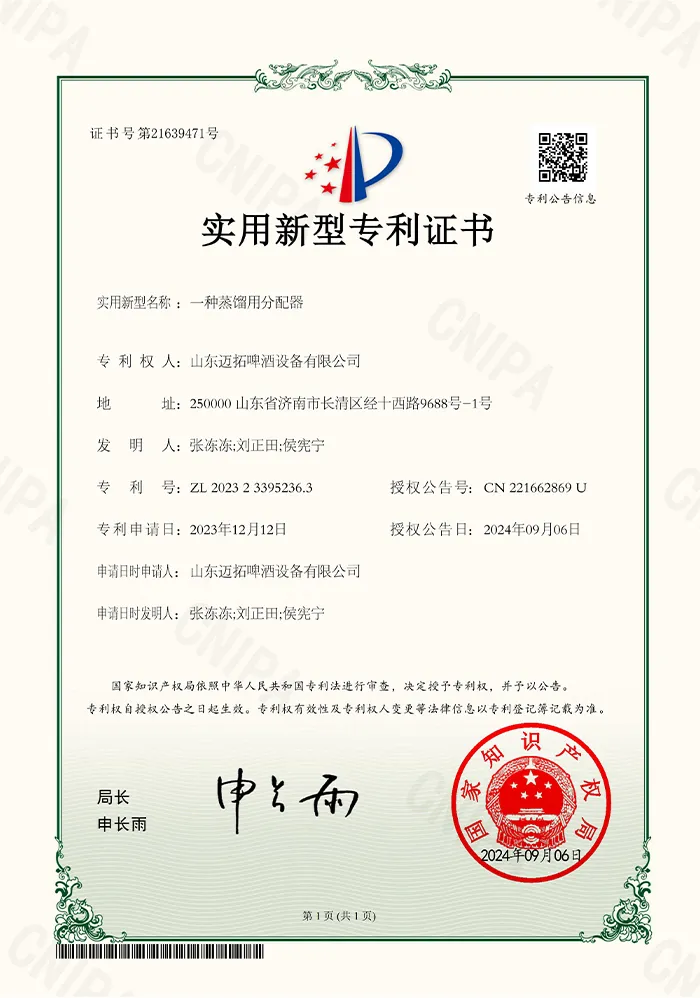

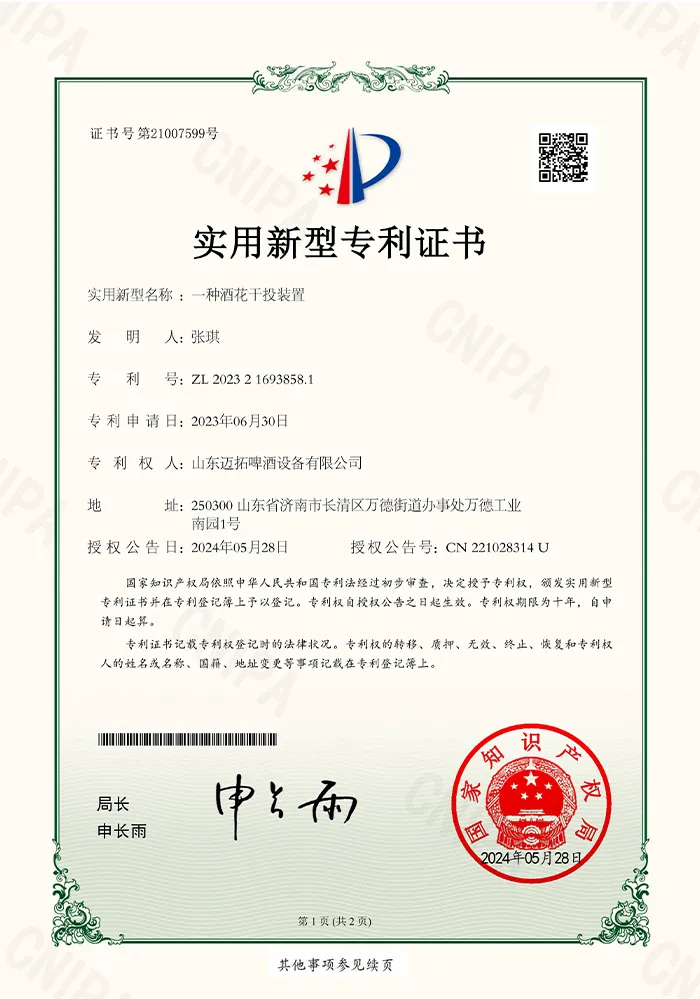

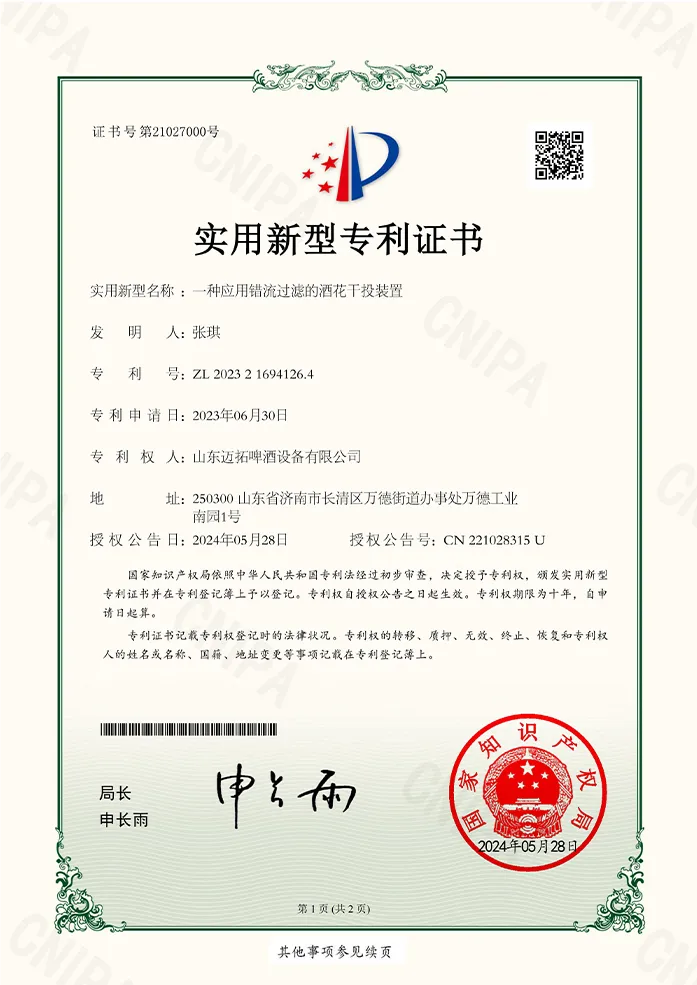

All of our brewing systems are manufactured in compliance with CE standards. We are audited by third-party authorities such as SGS and TUV