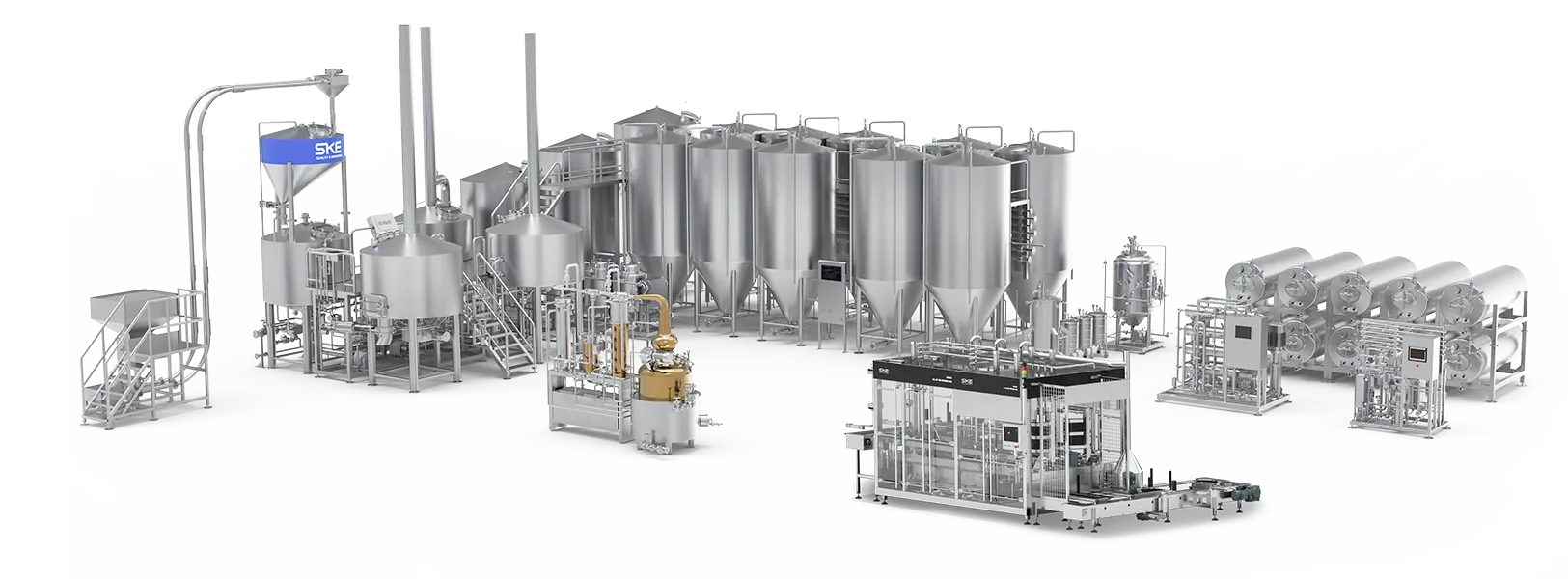

Auxiliary brewing equipment plays a critical role in ensuring stable production, hygienic operation, and process efficiency across the entire brewery. From wort transfer to yeast handling and process control, our auxiliary systems are engineered to integrate seamlessly into your brewhouse and cellar operations.

Auxiliary brewing equipment refers to the supporting systems that connect, protect, and optimize the core brewing process. While brewhouses and tanks perform primary functions, auxiliary equipment ensures smooth material flow, temperature stability, sanitation, and operational reliability throughout daily production.

Our auxiliary solutions are designed for craft breweries, microbreweries, and commercial brewing plants, supporting both new installations and system upgrades.

On September 10, a delega

Our auxiliary brewing equipment is engineered with a focus on hygienic design, process compatibility, and long-term operational stability. Each component is carefully selected and configured to ensure reliable performance, seamless system integration, and consistent results in daily brewery operations.

Food-grade SS304 / SS316 materials with hygienic connections and smooth internal surfaces.

Fully matched with brewhouse, fermenters, BBTs, and packaging systems.

Equipment sizing, flow rates, and layouts engineered to your specific brewing process.

Industrial-grade components selected for continuous brewery environments.

All auxiliary brewing equipment is manufactured and assembled in our 20,000㎡ stainless steel fabrication and system integration facility.

Quality process includes:

TIG welding with sanitary finish

Pressure and leak testing

Functional testing before shipment

Material and component traceability

CE / UL / PED compliant production where required

Each system is tested to ensure reliable operation before leaving our factory.

We design auxiliary equipment as part of a complete brewing process, not standalone products.

Direct control over quality, customization, and delivery schedules.

Auxiliary systems supplied to breweries in 60+ countries worldwide.

From layout design to commissioning and after-sales service.

Yes. All auxiliary systems are engineered based on your current equipment, process flow, and future expansion plans.

Absolutely. Auxiliary brewing equipment is a standard part of our turnkey brewery solutions.

SS304 or SS316 stainless steel, depending on process requirements and local standards.

Yes. We support manual, semi-automatic, and PLC-controlled auxiliary systems.