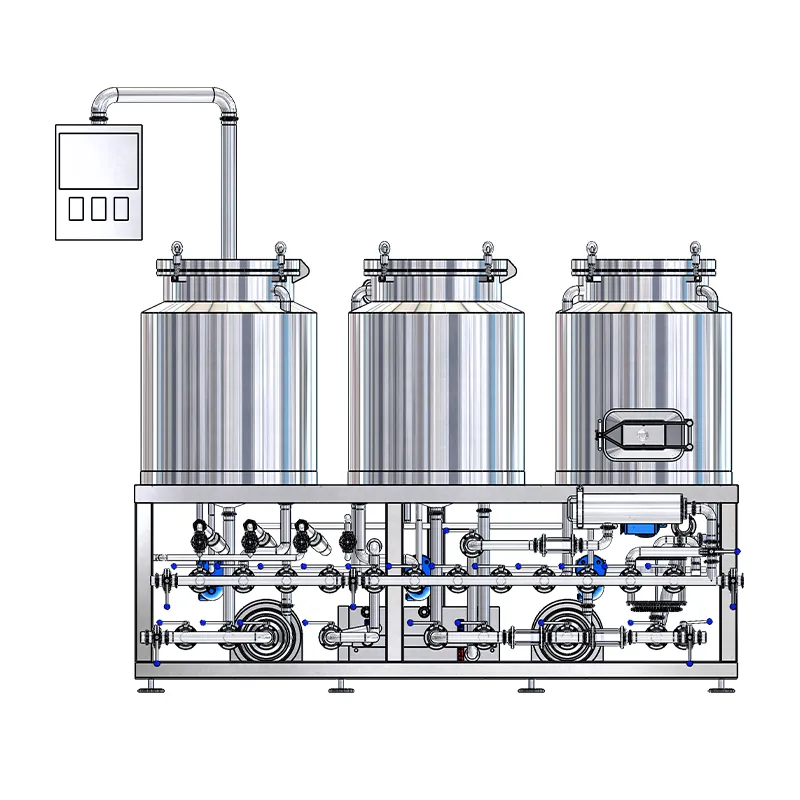

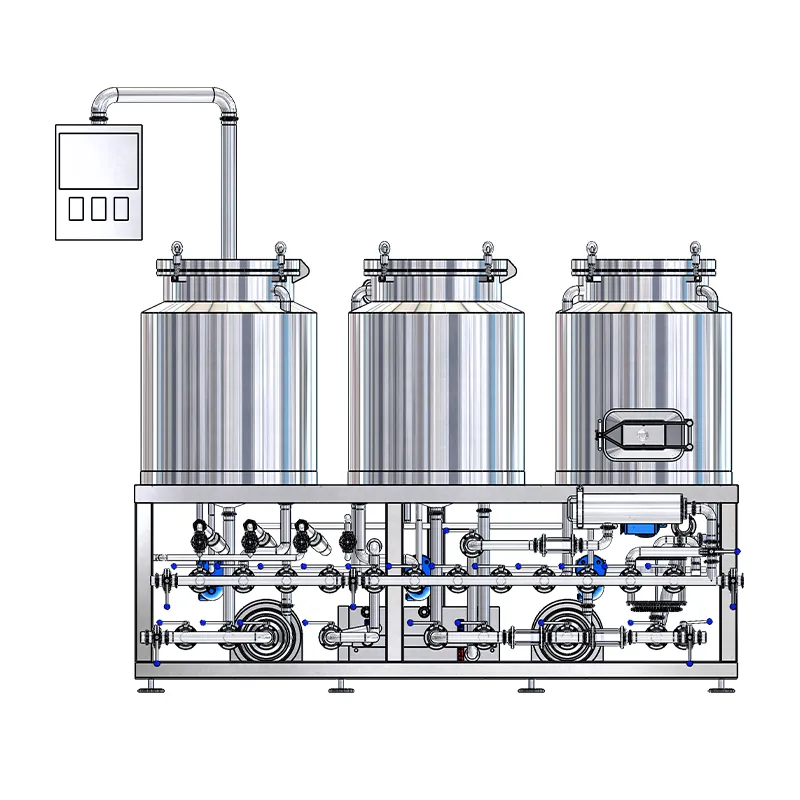

Explore our 100L nano brewery equipment designed for brewpubs, restaurants, and small batch production. Turnkey design, CE-certified, direct from China manufacturer.

Brewhouse Type | 2-vessel / 3-vessel (mash + lauter + kettle/whirlpool) |

Effective Volume | 100 Liters (1 BBL) |

Heating Method | Electric / Direct Fire / Steam (optional) |

Fermentation Tank | 2 x 100L conical fermenters with glycol jackets |

Bright Beer Tank | 1 x 100L with carbonation stone |

Control System | PID / PLC with Siemens/ABB components |

CIP Cleaning | Portable CIP cart with spray ball |

Material | Food-grade 304 stainless steel, 2B finish, passivated |

Power Supply | Customizable (220V / 380V / 415V) |

Footprint | 8–12 m² |

This system is ideal for small-scale production, recipe testing, or limited-space environments. It offers:

Whether you’re looking to start a nano brewery or run a test production line, our 100L system provides the perfect combination of cost, quality, and ease of use.

The price of a 100L nano brewing system typically ranges from USD 8,000–15,000, depending on configuration, automation level, and included accessories (such as glycol chiller, CIP system, or bottling line). We offer both entry-level manual setups and fully automated turnkey systems with PLC control.

Yes. Our 100L brewhouse is fully capable of brewing commercial-grade craft beer for restaurants, bars, and pilot sales. It uses the same stainless-steel construction, sanitary fittings, and temperature controls as larger systems, ensuring consistent product quality that meets market standards.

A 100L system typically produces 80–100 liters of finished beer per batch. With double-batch operation, you can brew up to 200L per day depending on your schedule, fermentation time, and available fermenter capacity. Scaling options are available if higher daily output is required.

A standard 100L nano brewery requires:

Power: 380V/220V depending on your local standard (customizable)

Water supply: 2–3 m³ per brewing cycle

Compressed air: Optional, for pneumatic valves or CIP use

Cooling water/glycol: For temperature control and fermentation cooling

We provide a complete utility layout guide during project planning to ensure smooth installation.

Absolutely. The 100L system is ideal as a pilot or experimental brewhouse for large commercial breweries. It allows testing new recipes, yeast strains, or brewing parameters before scaling production to 1000L or 5000L systems. All controls and processes mirror industrial setups, making data transfer seamless.

Ready to start your nano brewery journey? Contact our engineers for a free consultation and custom proposal.